SSV Valves | Manufacturer of Engine Valve Train Components

One of the largest manufacturers

of engine valve

Manufacturing Unit 1

- Plot No 2513, Kranti Gate - 1, H1 Road, Metoda GIDC, Rajkot - 360 021 Gujarat – INDIA.

Manufacturing Unit 2

- Plot No 2529 & 2530, Kranti Gate - 1, H1 Road, Metoda GIDC, Rajkot - 360 021 Gujarat – INDIA.

Registered Office

- 8/9 Rajyog Building, B/H Silver Chamber Tagore Road, Rajkot Pincode: 360 002 Gujarat, INDIA.

- +91 9925500009

- info@ssvalves.net

Follow Us On:

Our Products

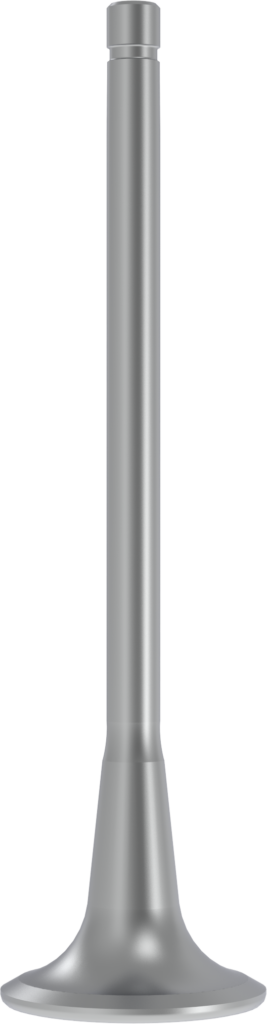

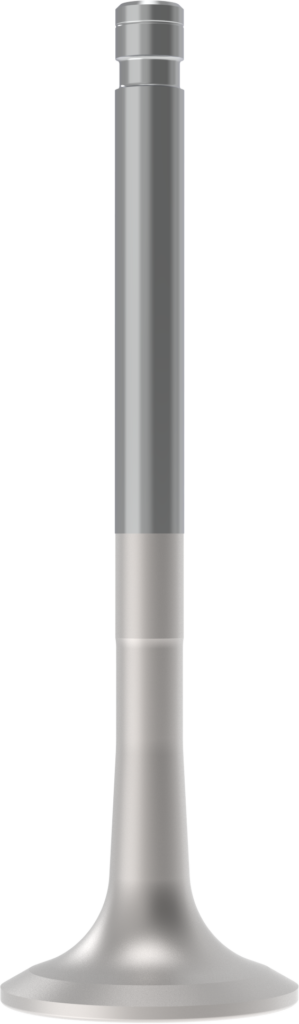

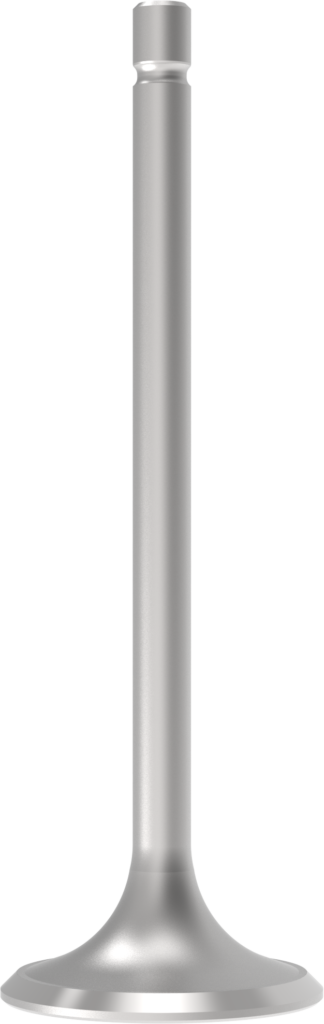

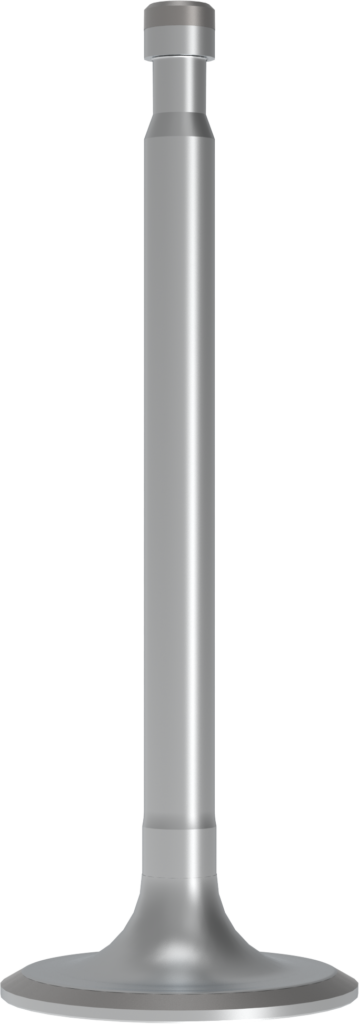

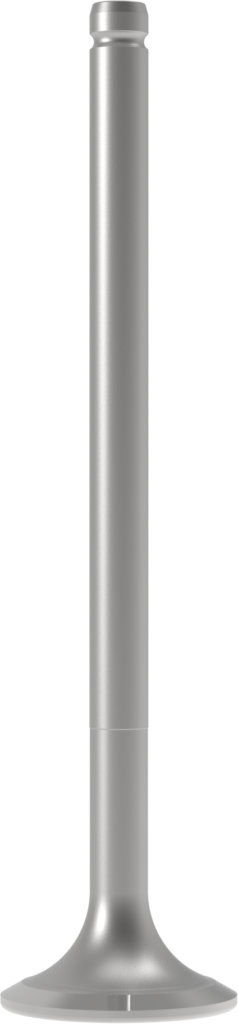

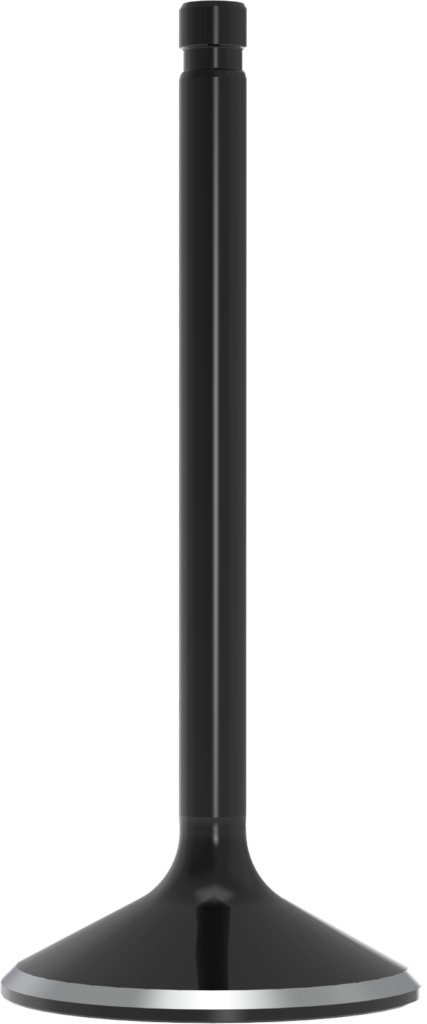

Engine Valves

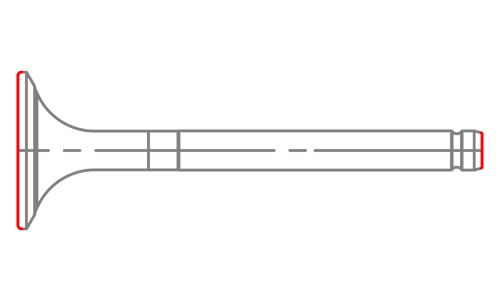

Engine valves are special mechanical component designed to be used in two-stroke and four-stroke internal combustion engines, which controls flow of fluids or gases into and from combustion chambers during operation.

By function, there are only two types of valves, inlet valve and exhaust valve. Inlet valves allow proper mixture of air and fuel to enter in combustion chamber, while exhaust valve opens to escape gases produced after combustion of air and fuel in camber. Inlet valve is exposed to low thermal stress, but exhaust valve has to undergo high thermal and mechanical stress due to its operation under high temperate and pressure.

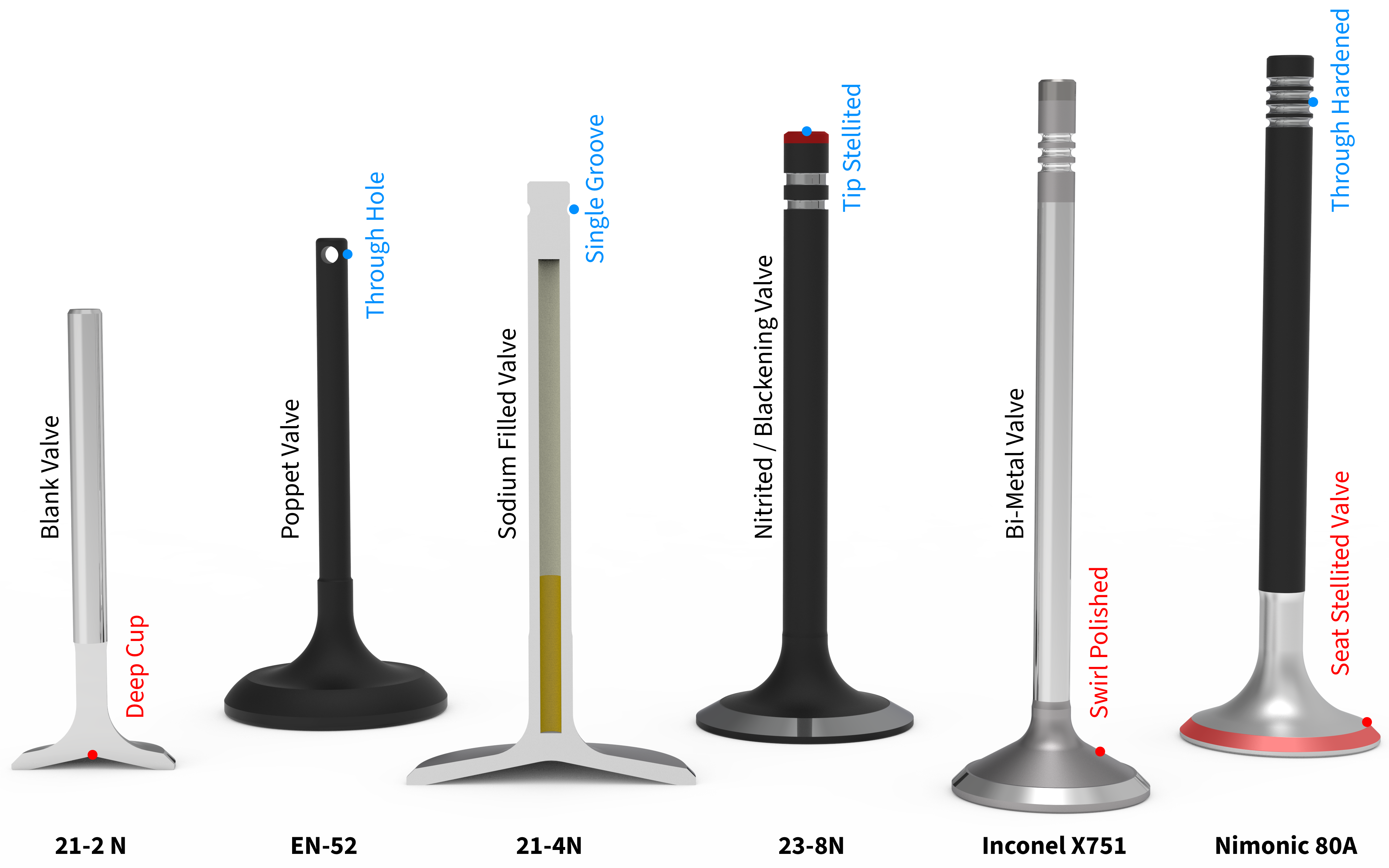

Generally, inlet valves are made of martensitic steel and exhaust valve are made of austenitic steels or high alloy steel. Based on their design, material and application, valves can be monometallic, entirely fabricated from a single metal, or bimetallic, fabricated using a friction welding process to have properties of austenitic head and martensitic stem.

Martensitic, Austenitic, Super Alloys & Hard Facing Alloys

Following OE Standards and Specification

4000 different types of Inlets and Exhaust Valve

Monthly Production of 300,000+ Pieces with Spare Capacity

Supplying to OEM and After Markets

Suitable for Vivid Applications

Depends on your need

Customized Range

Head

15 to 215 mm

Steam

4 mm to 35 mm

Length

55 mm to 750 mm

Delivered Performance, EVERY TIME

The highest point of thermal impact is on valve face seat, which is sometimes induction hardened or welded by cobalt alloy for long lasting. To improve its mechanical properties, valves are coated with chromium coating, phosphate coating and nitride coating. For better surface finishing, they are also swirl-polished.

SSV understand that engine valve is a vital component in every single engine, which bear heavy load to offer great performance using different fuels such us gasoline, diesel, kerosene, heavy fuel oil (HFO), dual fuel, marine diesel oil (MDO), compress natural gas (CNG), natural gas and landfill gas. We serve purpose of every client whether it is an engine rebuilder, engine maker, original equipment manufacturer, overhauling company, refurbish or trader. We ensure that every valve produced is quality-checked thoroughly.

Delivered Performance, EVERY TIME

The highest point of thermal impact is on valve face seat, which is sometimes induction hardened or welded by cobalt alloy for long lasting. To improve its mechanical properties, valves are coated with chromium coating, phosphate coating and nitride coating. For better surface finishing, they are also swirl-polished.

SSV understand that engine valve is a vital component in every single engine, which bear heavy load to offer great performance using different fuels such us gasoline, diesel, kerosene, heavy fuel oil (HFO), dual fuel, marine diesel oil (MDO), compress natural gas (CNG), natural gas and landfill gas. We serve purpose of every client whether it is an engine rebuilder, engine maker, original equipment manufacturer, overhauling company, refurbish or trader. We ensure that every valve produced is quality-checked thoroughly.

Friction Weld Valve

Hard Chrome Valve

Swirl FinishValve

Phosphate/Nitrite Finish Valve

Induction Hardened Valve

Seat/Tip - ArmouredValve

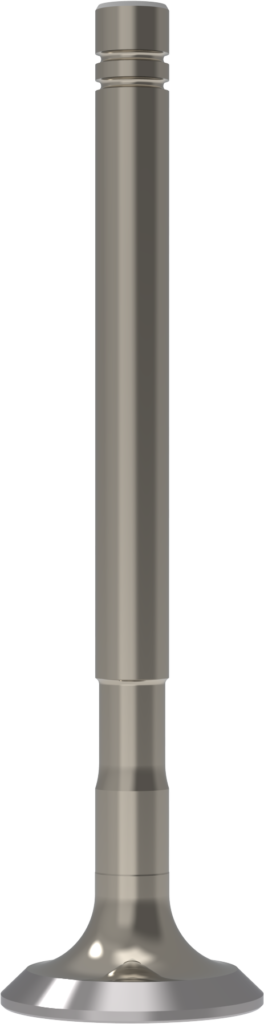

MonoMetallicValve

BiMetallicValve

Inconel X751 Valve

Nimonic 80A Valve

Titanium Valve

Tribaloy Valve

Engineering behind Manufacturing

One of the most critical part of Valve Train Assembly is Engine Valves, which must be carefully manufactured for its excellent performance. Our proficiency ensures the right combination of materials, performance, process, heat treatment and coating for genuine reliability, based on customer’s application and its use. With in-deep knowledge of standard and high alloy steels, we offer solutions to reduce high-wear out of value performing under temperature and pressure.

Every valve we manufacture is carefully crafted to perfection to provide high efficiency and longevity of premium engines. With cost effective automation process and implementation, we strike a balance between quality and affordability.

Proactively meeting customer expectations is what we do at SSV, every day.

SIMPLIFY THE QUALITY, DETERMINE THE PRODUCT