SSV Valves | Manufacturer of Engine Valve Train Components

One of the largest manufacturers

of engine valve

Manufacturing Unit 1

- Plot No 2513, Kranti Gate - 1, H1 Road, Metoda GIDC, Rajkot - 360 021 Gujarat – INDIA.

Manufacturing Unit 2

- Plot No 2529 & 2530, Kranti Gate - 1, H1 Road, Metoda GIDC, Rajkot - 360 021 Gujarat – INDIA.

Registered Office

- 8/9 Rajyog Building, B/H Silver Chamber Tagore Road, Rajkot Pincode: 360 002 Gujarat, INDIA.

- +91 9925500009

- info@ssvalves.net

Follow Us On:

Home > Unveiling the Powerhouse: A Dive into Sodium-Filled Valve Manufacturing

Unveiling the Powerhouse: A Dive into Sodium-Filled Valve Manufacturing

In the realm of high-performance engines, where every degree of temperature can make a difference, sodium-filled valves stand out as a pinnacle of engineering innovation. These valves, designed to excel in extreme conditions, play a vital role in ensuring optimal performance and reliability. Join us as we delve into the intricate world of sodium-filled valve manufacturing, uncovering the secrets behind their construction, materials, and unparalleled benefits.

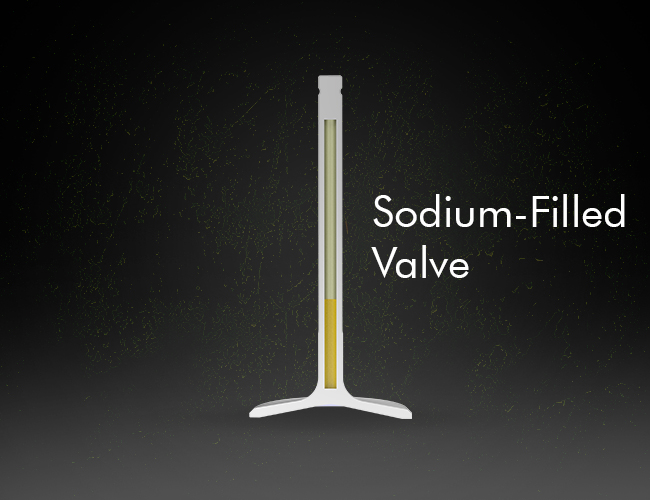

Construction and Design

At the heart of a sodium-filled valve lies a carefully engineered design that sets it apart from conventional valves. Unlike traditional valves, which are solid throughout, sodium-filled valves feature a hollow cavity inside the valve stem. This cavity is meticulously filled with elemental sodium, a remarkable conductor of heat. This innovative design allows for efficient heat transfer from the valve head to the sodium-filled stem, promoting superior cooling capabilities.

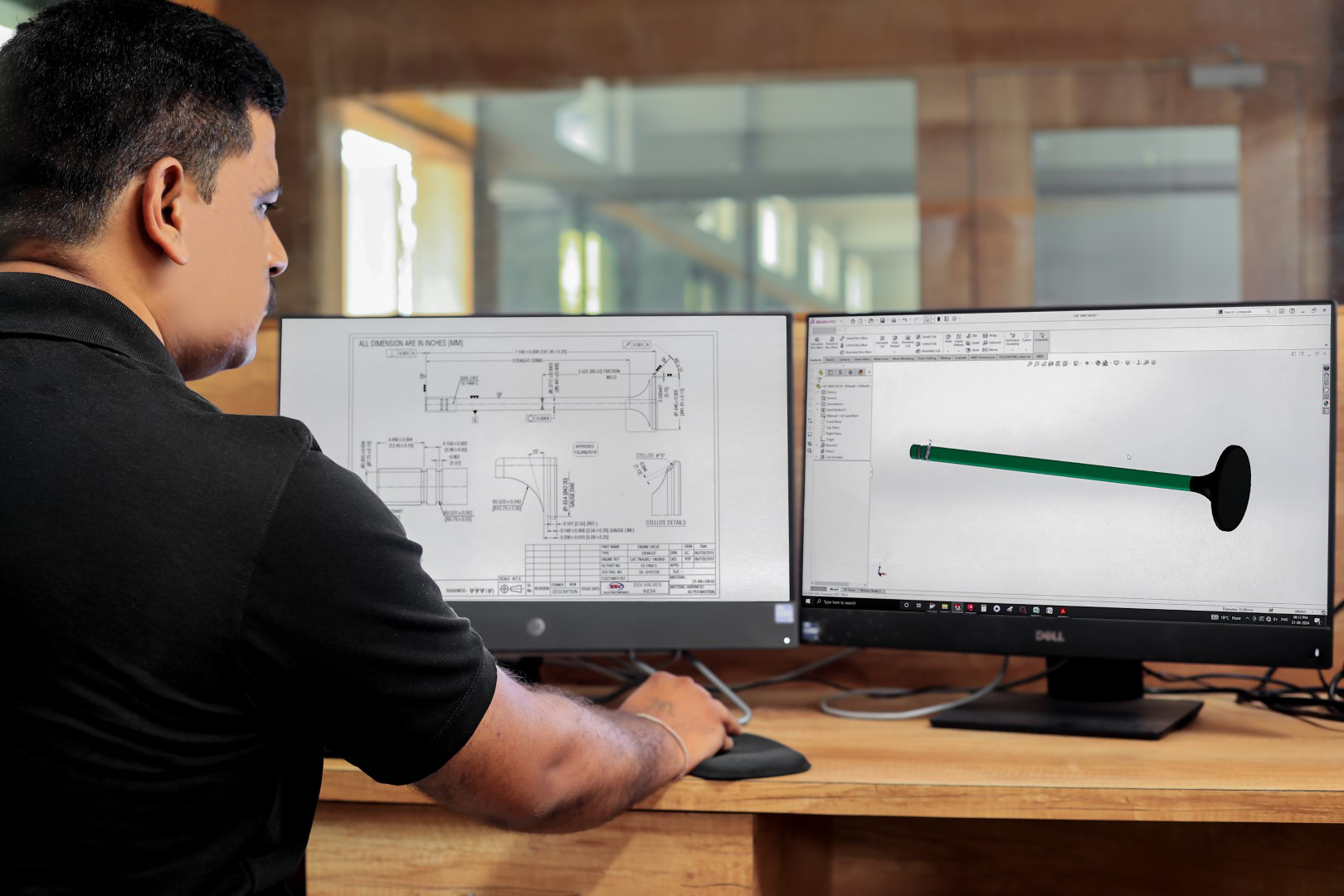

Manufacturing Process

Crafting sodium-filled valves is a precise and intricate process that requires advanced manufacturing techniques. The journey begins with the selection of high-quality materials capable of withstanding the extreme temperatures and pressures encountered in high-performance engines. Once the materials are chosen, the manufacturing process typically involves precision forging and machining to shape the valve components to exact specifications. Finally, the valves undergo a specialized sodium-filling process, where the hollow cavity inside the valve stem is carefully filled with elemental sodium to maximize heat transfer efficiency.

Materials Used

The materials used in sodium-filled valve manufacturing are paramount to their performance and durability. These valves are typically constructed from high-temperature-resistant alloys, such as stainless steel or titanium, which can withstand the demanding conditions of high-performance engines. Additionally, the use of high-quality materials ensures that sodium-filled valves maintain their structural integrity and functionality even under the most extreme operating conditions.

Benefits of Sodium-Filled Valves

Sodium-filled valves offer a myriad of benefits that make them indispensable in high-performance engine applications. One of the primary advantages is their unparalleled heat dissipation capabilities. By efficiently transferring heat away from the valve head, sodium-filled valves help maintain optimal operating temperatures, preventing overheating and thermal degradation. Furthermore, the enhanced cooling provided by sodium-filled valves contributes to increased durability and longevity, ensuring reliable performance in demanding environments.

Applications

The versatility and performance of sodium-filled valves make them ideal for a wide range of high-performance engine applications. From racing cars and aircraft engines to high-performance motorcycles, sodium-filled valves are trusted by engineers and enthusiasts alike to deliver exceptional performance and reliability. Whether on the racetrack or in the skies, sodium-filled valves continue to push the boundaries of engine technology, powering vehicles to new heights of speed and efficiency.

Conclusion

Sodium-filled valve manufacturing represents the epitome of precision engineering and innovation, offering unparalleled performance and reliability in high-performance engine applications. Through meticulous design, advanced materials, and specialized manufacturing processes, sodium-filled valves continue to redefine the limits of what's possible in engine technology. As engines evolve and demand for higher performance grows, sodium-filled valves stand ready to meet the challenges of tomorrow, driving innovation and excellence in the world of automotive and aerospace engineering.

Share

Category

- Blog (4)

- Featured Blogs (3)

- Recent Participation (3)

Recent Posts

SIMPLIFY THE QUALITY, DETERMINE THE PRODUCT