Engine Valve

SSV manufactures internal combustion engine Valves. There are mainly two different types of valves used in internal combustion

engines, differentiated as Intake Valve and Exhaust Valve.The valves called Intake engine valves let fuel and air mixture

get into the cylinder and the Exhaust Valve lets the evacuate out of the cylinder.This process takes place continuously in

the engine to run.

From intake to exhaust Engine Valve, you can rely on SSV for Accurate Quality, Best Performance, and Real Value. We manufacturer special allow engine valves such as Titanium Engine Valves, Inconel engine Valves, Triballoy engine Valves, Nimonic Engine Valves, Swirl polished engine valves, Chromium plated engine valves, Phosphate pated engine valves, Nitrite engine valves, Deflector engine valves, Bimetal engine valves, and custom engine valves as per the requirement of our respected customers.

Special Processes of Engine Valve

SSV is specialized in manufacturing varieties of Engine Valves making use of all kind of materials.

Following are the special processes which are performed on the valve resulting the best quality.

For engine valves distributors who requires different metallic composition SSV is able to produce accordingly by offering

number of valve grade, which will meet American, European and Japan standards along with our manufacturing and quality standards.

Titanium engine valves

Titanium engine valves are used mainly in the high performance racing industry.

SSV titanium engine valves are manufactured

using best quality TI alloys. Titanium valve offers high temperatures resistance to assure peak performance. SSV is having all Titanium

High Performance Series.Also featuring single or multi-layer coating such as

chromium nitrite (CrN) or

titanium nitrite (TiN), for

increasing life span for highly heat resistance. SSV produces titanium engine valves for all high performance racing applications,

from American countries, European countries, through professional sport applications.

INCONEL alloy 751 (UNS N07751) is a precipitation hard enable nickel-chromium alloy, used mainly for the exhaust valves of internal combustion engines.

The alloy has essentially the same excellent physical, mechanical and corrosion-resistance properties as INCONEL alloy X-750.In the evaluation of materials

for exhaust valve applications, nickel-chromium alloys have performed well in a 1675°F (913°C) lead oxide screening test.

INCONEL alloy 751 repeatedly offered good results, with corrosion rates averaging 4.31 g/dm2/h. Like other

nickel-chromium alloys,

INCONEL alloy 751 also resists

attack by other exhaust stream impurities such as sulfur, bromine and chlorine.

TRIBALOY Alloys

1. Conventional Tribaloy alloys

Tribaloy alloys are cobalt-based or nickel-based alloys which are primarily strengthened by inter metallic Laves phases dispersed in a softer eutectic matrix,

and are corrosion and wear resistant. The eutectic solid solution provides high mechanical strength, fracture toughness, and ductility, while the Laves phase which

are formed by molybdenum and silicon, gives the materials wear resistance under poor or unlubricated conditions. Molybdenum and silicon improve the wear resistance

and the corrosion resistance comes from adding chromium to the alloy. Conventional They usually have low strength and fracture toughness in comparison with ductile

materials, owing to the large volume fraction of Laves .

2. Newly developed Tribaloy alloys

In order to improve ductility and enhance corrosion resistance of Tribaloy alloys, two new Tribaloy alloys, designated as T-401 and T-400C, as a modification of T-400.

NIMONIC alloy 80A

NIMONIC alloy 80A (UNS N07080/W. Nr. 2.4952 and 2.4631) is a wrought, age-hard enable nickel-chromium alloy, strengthened by additions of titanium,aluminium and

carbon, developed for service at temperatures up to 815°C (1500°F). It is produced by high-frequency melting and casting in air for forms to be extruded. Electro slag

refined material is used for forms to be forged. Vacuum refined versions are also available.

NIMONIC alloy 80A is currently used for gas turbine components

(blades, rings and discs), bolts, nuclear boiler tube supports, die casting inserts and cores, and for automobile exhaust valves.

Specialized in making

Stellite Engine Valve.

Stellite is a group of

cobalt-based alloys welded in the seat of exhaust

valves, that is

very resistant to wear and high temperatures.

The

Swirl Polished Engine Valves are mostly used in high performance racing

engines.The

swirl polished Valve has sharp edges and improves the flow, increases

the speed doesn't

matter in which direction the swirl is.These valves are stronger

than non polished valves.

The

Chrome plated Engine Valve are

manufactured by

plating chrome on the stem of the valve.

It lengthens durability in the valve and increases stem resistance.

Engine Valves

Engine Valves are plated with phosphate for maintaining lubrication and protect against corrosion.

Nitration is hardening process of

coating nitrite on the engine valve which will appear as black valve. Compared to stainless steel base material

the micro hardness is higher having high ductility property beneath the nitrated layer. The nitrite coating increases the deterioration and

corrosion resistance. The Black Nitrite applies to the whole valve and the nitrite layer is stick to the base material at a microscopic level,

so the valve does not break when in bend due to impacts with the pistons. Nitration processed on valve decreases stickiness and this features

lengthen valve durability.

The

Deflector Engine Valves are also manufactured maintaining the best Quality.

The regular alloy material is used in manufacturing of these valve. There are two types of steel,

Austentic steel and

Martensitic steel.

Some valves are magnetic and some valves are non magnetic depending upon the engine sustaining the valve.

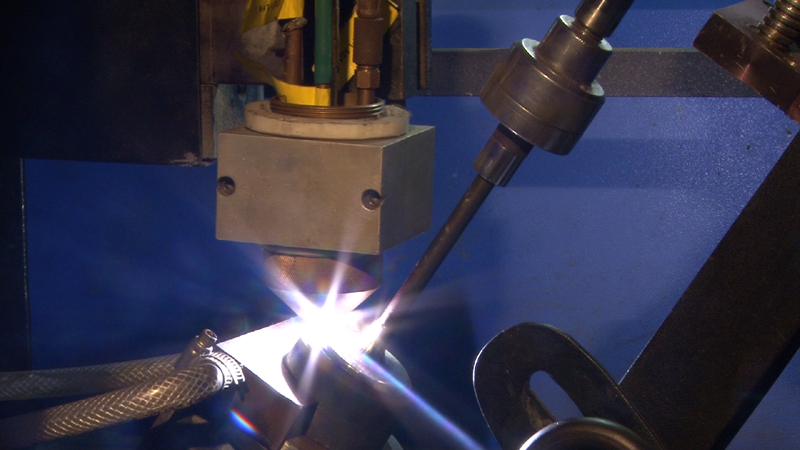

The engine valve made up of two different metals are knows as

bi-metal Valves. This is done using friction welding process.

Exhaust valves are especially made from bi-metal. Austentic Steel which is having heat resistance and corrosion resistance properties,

is used at the head while the stem is made from Martensitic Steel which have high tensile strength and abrasive wear resistance property.

This technique is mainly used in high stressed exhaust valves.

Engine Valve for all the range world wide.

AGRALE , ALFA ROMEO , AUDI , AUTOBIANCHI , BAUDOUIN , BEDFORD , BEDFORD DIESEL , BMW , BMW DIESEL , CATERPILLAR ,

CIRTOEN , CUMMINS , DAF DIESEL , DAIHATSU , DAEWOO , DEUTZ , DODGE , FIAT , FIAT DIESEL , FIAT IVECO , FIAT TRACTORS ,

FORD , FORD DIESEL , FORD TRUCK , FORD , COMMERCIAL. INDUSTRIAL. AGRICULTURAL , HILLMAN , HONDA , HINO , HYUNDAI , INTERNATIONAL,

ISUZU, ISUZU DIESEL, K.D.H KLOCKNER-HUMBOLDT-DEUTZ , KAWASAKI , KOMATSU , KUBOTA , LADA , LISTER , LANDROVER , M.A.N. ,MAZDA,

MERCEDES DIESEL , MISTUBISHI , M.W.M. , NISSAN , NISSAN DIESEL , OPEL , PERKINS , PETTER , PEUGEOT , PIAGGIO , RENAULT , SCANIA ,

SUZUKI , SUBARU, TOYOTA , UNIVERSAL,VOLKSWAGEN,VOLVO , WILLYS JEEP , YAMAHA , YANMAR , ZETOR